Soap making is a wonderfully creative craft that people of all ages can enjoy. The only limit is your imagination, with the wide variety of oils, fragrant essential oils, and other natural additives you can use to make your soaps one of a kind. Here are the basic soap-making steps you can follow to begin your adventure.

Equipment:

Most of the equipment you need to make cold-pressed soaps at home is likely already in your kitchen. You will need the following:

- Kitchen scales to accurately measure your ingredients.

- Soap pot. This should be made of unchipped enamel or stainless steel. This should be large enough to hold your soap batch and allow for stirring and mixing without splashing.

- Heat-resistant jug for mixing your caustic soda (lye) solution. As the solution heats up significantly when caustic soda is added to the water, the jug should be microwave-safe to handle this heat.

- A handheld or stand-alone mixer or a stick blender.

- Two kitchen thermometers will allow you to measure in the 34 to 38 degrees range for the recipe on this page. Other recipes may require a different temperature range.

- Safety glasses or goggles should be worn to protect your eyes whenever you are handling soap-making ingredients.

- Rubber gloves to protect your hands when handling soap-making ingredients.

- A sharp knife for slicing bars of soap or a soap cutter.

- A soap mould or a large plastic container to use as a soap mould. An empty cardboard milk carton can make a suitable soap mould if you don’t have anything else.

- An old blanket or towel for wrapping your soap in once the moulds.

- A plastic needlepoint screen, sushi mats, or a similar item to place your soaps on to cure.

Ingredients for Cedarwood and Green Clay Soap:

- 120 grams of caustic soda

- 300 grams of distilled water

- 200 grams of Coconut oil

- 200 grams of Sustainable palm oil

- 400 grams of Olive oil

- 50 grams of Sweet Almond oil

- 15 ml of Cedarwood essential oil

- 1/8th of a teaspoon of Starlight Green Mica

Safety: When added to water, caustic soda causes a significant increase in temperature. It is also a strong alkaline solution and can cause burns when it comes into contact with your skin. You must be careful not to spill or splash any on yourself during the soap-making process. If you get any on your skin, rinse it immediately with cold, running water. Always wear your safety glasses, goggles, and rubber gloves before handling caustic soda. Always add caustic soda to the water, not the other way around. Even after you have mixed the caustic soda solution with your oils and created a soap, the soap mixture can still burn you, as the saponification process is not complete until the soap is cured. The soap mixture remains alkaline and can still cause burns.

Instructions:

- Before you begin your soap-making, gather all the necessary equipment and ingredients. There is nothing worse than being partway through a soap recipe and discovering you lack an essential ingredient. Soap making is a time- and temperature-sensitive process, and you cannot stop what you are doing to go to the store and pick up what you don’t have.

- Put on your rubber gloves and your safety goggles. Using an accurate kitchen scale, carefully weigh out all your ingredients. I measure my caustic soda first, then place it into a small dry bowl. Then measure your distilled water and place it into your jug. Measure each of your oils and place them all together into your soap pot or stainless steel bowl.

- Mix your caustic soda solution. Always add your caustic soda to your water. DO NOT ADD WATER TO YOUR CAUSTIC SODA. The chemical reaction can produce significant heat, resulting in fizzing and splattering. Mix the caustic soda into the water. It is best to do this outside or in a well-ventilated room if possible. You do not want to breathe in any of the fumes that can be created during this initial chemical reaction. Your caustic soda solution will become quite hot and needs to cool down before it can be added to your oil. Once I have mixed up my caustic soda solution, I carefully place one of my thermometers into the jug to monitor the temperature as it cools.

- While you wait for the caustic soda solution to cool, melt your oils in your soap pot. Place your second thermometer into the bowl of oils so that you can monitor the oil’s temperature.

- Once you have your caustic soda solution prepared and your oils melted, you must equalise their temperature until they are the same, somewhere between 34°C and 38 °C. To do this, use hot and/or cold water in the sink and place the jug and/or bowl into the appropriate water. My kitchen has a double sink, so I usually cool the caustic soda solution in one sink while I keep my oils warm in the other. When they reach the same temperature, you are ready to mix them together. This may take a little practice, but once you have made a few batches, it becomes quite easy as you become accustomed to how long the caustic soda solution takes to cool down from its initial heat reaction and how long it takes for the oils to warm up.

- Once the oils and the caustic soda solution reach the same temperature range, you can pour the caustic soda solution into your oil mixture. Wearing rubber gloves and safety glasses, slowly drizzle the caustic soda solution into your oils while mixing. If you plan to use a free-standing or hand mixer, set it to its lowest speed. A free-standing mixer allows you to move away when mixing and avoid getting any small splashes on you. If you use a handheld mixer or stick blender, be sure to have long sleeves and rubber gloves, and that the bowl is large enough to work without getting splashed. It is faster with a stick blender.

- Keep mixing until the soap mixture starts to thicken. As the mixture starts to thicken, you need to test for trace. To test for trace, use a spoon to pick up a small amount of the soap mixture and drizzle it across the top of the remaining soap mixture. If it is not ready, the drizzle will immediately sink back into the soap mixture, without leaving a trace. However, as it thickens and you test the mixture again, a small amount of the soap mixture, when drizzled onto the remaining soap mixture, will leave a faint pattern before sinking back into the mixture. This is called

trace . You do not want to wait until the trace is thick enough for the pattern to remain on the surface, as this will then be too thick to pour.

- Once your soap has reached trace, you can mix in your essential oil and mica. Mix these in, and then immediately pour your soap.

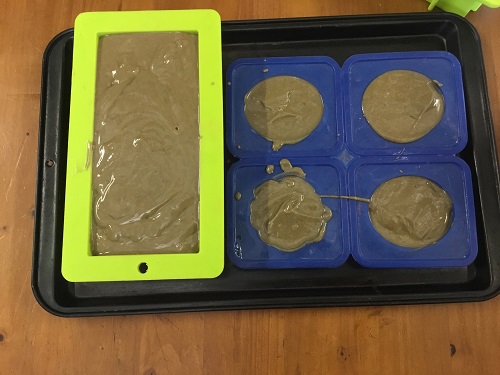

- If using silicone soap moulds, place them onto a tray, such as a baking tray. Carefully pour your soap into the mould(s). You can use a spatula to get every last bit of soap out. Do not overfill them. If the surface is not smooth after you poured your soap, give it a gentle shake, and it will smooth out. The same applies if you are using some other container as a mould.

- Cover your soaps with another tray or a cardboard box. Wrap your mould(s) in insulating material such as a blanket or old towels to keep them warm. Place them in a warm location. I usually use my kitchen, as this is the warmest room in my house.

- Allow your soap to set undisturbed for 24 to 48 hours.

- Check your soaps for firmness. They should be firm to the touch but not rock-hard. If it is still too soft to remove from the mould(s) without damaging the shape of the soap, leave it for a longer period. Once it is firm to the touch, simply pop the soap out of the mould. Place your soaps on a plastic needlepoint screen, sushi mats, or something similar to air dry. You want something that will allow air to circulate around the soap. Turn your soap over once a week.

- Allow your soap to cure for six weeks before using it. This allows for the saponification to be completed.

This simple recipe has no special effects, but I like soap like that. That does not mean I don’t want to get crazy creative sometimes, and I am sure I will post a few of those creations in the future, just for fun.

As always, live well.

Valerie

Making soap is so much fun, Valerie. I have been using some of your micas for colour as I have problems with the clay sometimes. I never do with the micas though.