There are a lot of shaving creams and soaps out there, all coming in various types of containers and all different price ranges. Everything from inexpensive cans of foam for under $5.00 to custom-made, high-quality soaps starting at about $25.00 and going up from there. So while I could purchase this item from the store, or online, I prefer to make my own, both for myself and for my family.

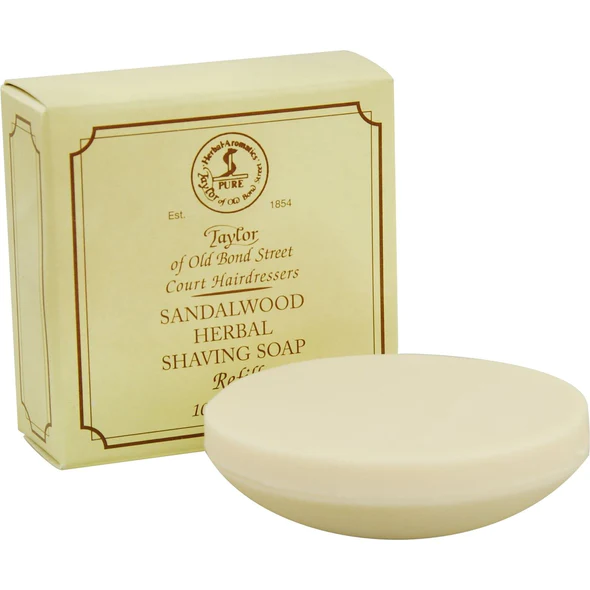

Indeed, I do not save money making my shaving soap if I compare the cost of the ingredients with the cost of a can of Gillette shaving foams. But if I am comparing the cost of my hand-made shaving soap to something like Taylor shaving soap pictured below, I am coming out far better of by taking the time to make my own.

So what’s wrong with purchasing a can of shaving cream? I am glad you asked.

- The can. I am pretty sure that the environment could do without another throw-away can. This buy-it, thrown-it-away, and forget-it culture we live in is not sustainable. It might be cheap in dollars, but it is costing us the world, literally.

- The ingredients such as Butane and Sodium Lauryl Sulfate (SLS). There is evidence of these being skin irritants, so I don’t want to use them on my skin.

Ok, so the can is out. When it comes to the more expensive hand-made shaving soaps, I love them. The cost is the issue here. Especially when they are so easy to make yourself. Here is a simple recipe to get you started.

DIY Spearmint Shaving Soap

Equipment

- Digital scales to accurately measure your ingredients.

- Soap pot. This should be made of unchipped enamel or stainless steel, large enough to hold your batch of soap and allow for stirring and mixing without splashing.

- Heat-resistant jug for mixing your caustic soda (lye) solution. As the solution heats up significantly when caustic soda is added to the water, the jug should be microwave safe to handle this heat.

- A hand-held or stand-alone mixer or stick blender.

- Two kitchen thermometers that will allow you to measure in the range of 40 to 45 degrees.

- Safety glasses or goggles to protect your eyes whenever you are handling soap-making ingredients.

- Rubber gloves

- Soap moulds or a jar to use as a soap mould.

- An old blanket or towel for wrapping your soap in the mould(s).

- Plastic needlepoint screen, sushi mats or something similar, to place your soaps on to cure.

Ingredients:

- 47 grams of caustic soda

- 105 grams of non-chlorinated water

- 96 grams of coconut oil

- 96 grams of palm oil

- 32 grams of castor oil

- 48 grams of sunflower oil

- 32 grams of olive oil

- 16 grams of cocoa butter

- 1 teaspoon of clay (Bentonite or other Australian clay)

- 1/4 teaspoon spearmint essential oil

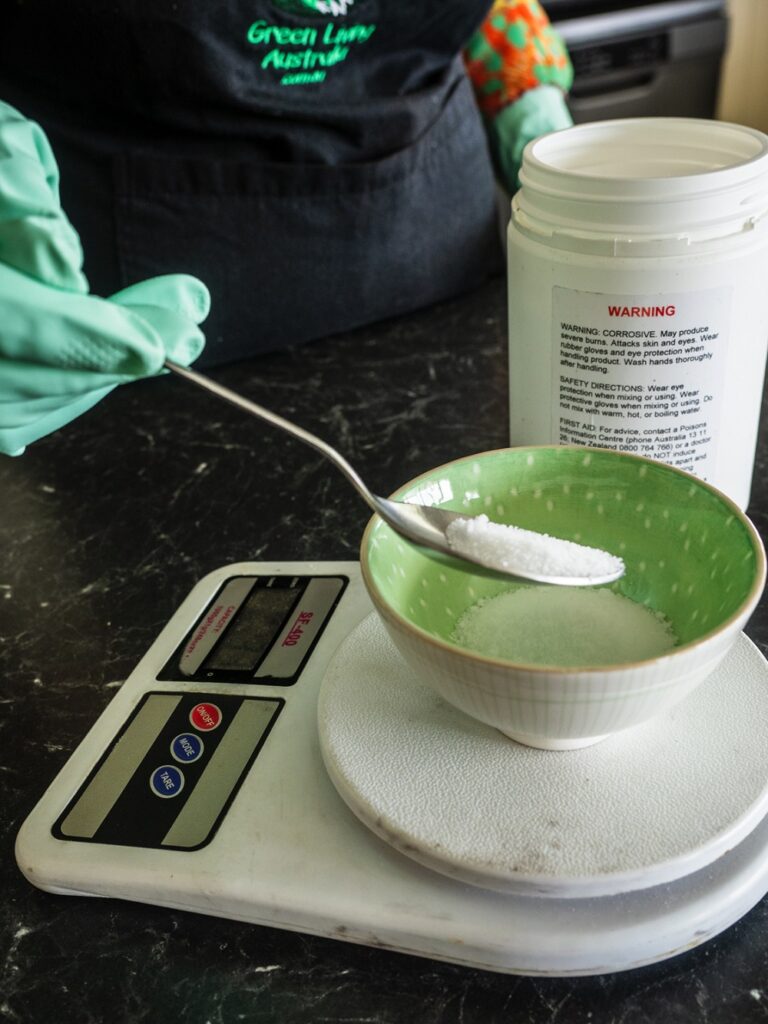

Safety: Caustic soda, when added to water, increases in temperature significantly. It is also a strong alkaline solution and will burn when it comes into contact with your skin. You must be very careful not to spill or splash any on you at any time during the soap-making process. If you do get any on your skin, immediately rinse it off in cold running water. Always put on your safety glasses or goggles and your rubber gloves before handling caustic soda. Always add caustic soda to the water and not the water to the caustic soda. Even after you have mixed the caustic soda solution in with your oils and have a soap, this soap mixture can still burn you as the saponification process is not complete until the soap is cured, and the soap mixture is still very alkaline and can still burn you.

Instructions:

- Before you start your soap-making, gather all the equipment you will need and all your ingredients. There is nothing worse than being partway through a soap recipe and discovering you do not have something you need. As soap making is a time and temperature-sensitive process, you will not be able to stop what you are doing and pop out to the store to pick up what you do not have.

- Put on your rubber gloves and your safety goggles. Using accurate kitchen scales, carefully weigh out all your ingredients. I measure my caustic soda first, then place it into a small dry bowl. Then measure your distilled water and place it into your jug. Measure each of your oils and place them all together into your soap pot or stainless-steel bowl.

- Mix your caustic soda solution. Always add your caustic soda to your water. DO NOT ADD WATER TO YOUR CAUSTIC SODA. The chemical reaction can cause significant heat production, fizzing, and splattering. Use your wooden spoon to mix the caustic soda into the water. If possible, it is best to do this outside or in a well-ventilated room. You do not want to breathe in any of the fumes that can be created during this initial chemical reaction. Your caustic soda solution will become quite hot and will need to cool down before it can be added to your oil. Once I have my caustic soda solution mixed up, I carefully place one of my thermometers into the jug so that I can monitor the temperature as it cools.

- While you are waiting for the caustic soda solution to cool down, melt your solid oils using your soap pot. Add your liquid oils to your melted solid oils then place your second thermometer into the bowl of oils so that you can monitor the oil’s temperature.

- Once you have your caustic soda solution made up, and your oils melted, you will need to equalise their temperature until they are the same, somewhere in the range of 40 to 45 degrees. To do this use hot and/or cold water in the sink and place the jug and/or bowl into the appropriate water.

- Once the oils and the caustic soda solution reach the same temperate, or within a few degrees, you are ready to pour your caustic soda solution into your oil mixture. Wearing rubber gloves and your safety glasses slowly drizzle the caustic soda solution into your oils while mixing. If you are going to use a free-standing or hand mixer it should be set at its lowest speed. A free-standing mixer allows you to move away when mixing and avoid getting any small splashes on you. If you are using a handheld mixer or stick blender, be sure you have long sleeves and rubber gloves and that the bowl is big enough so that you can work without getting splashed. It is faster with a stick blender.

- Keep mixing until the soap mixture starts to thicken. As the mixture starts to thicken you need to test for trace. To test for trace, use a spoon and pick up a small amount of the soap mixture and drizzle it across the top of the remaining soap mixture. If it is not ready, the drizzle will immediately sink back into the soap mixture without leaving a trace. However, as it thickens and you test the mixture again, a small amount of the soap mixture drizzled onto the remaining soap mixture will leave a faint pattern before sinking back into the mixture. This is called a trace. You do not want to wait until the trace is thick enough for the pattern to remain on the surface, as this will be too thick to pour.

- Once your soap has reached trace, you are ready to mix in your essential oil and clay. Mix these in and then immediately pour your soap.

- If using silicone soap moulds, place them onto a tray, such as a baking tray. Carefully pour your soap into the mould(s). You can use a spatula to get every bit of soap out. Do not overfill them. If the surface is not smooth from when you poured your soap, give them a little shake and they will smooth out. Otherwise, if your batch has become thick, smooth it out with a spatula as much as possible. The same applies if you are using some other container as a mould.

I filled this jar and also used a silicon mould to make a few blocks as well. I like the idea of the jar because it is so easy to wet the brush and then make the foam right in the jar. So easy to use.

As this is a cold process soap, you will need to leave it to cure for about 6 weeks. It is still a little caustic when it is first made, and the curing time is necessary to make a soap that is not going to irritate the skin. This recipe uses cocoa butter and feels amazing on the skin, leaving it feeling silky smooth.

I hope that you enjoy this recipe and that it helps you live a more sustainable life,

As always, live well.

Valerie